News & Events

Announcements

Congratulations to Brendan McGrew (Mechanical Engineering '28, Navy ROTC scholarship Midshipman) who won first prize in the midshipmen and cadets category of the 2025 Chief of Naval Operations Naval History Essay Contest for his piece, Hollow Navy: A Defensive Force with Little to Defend. The essay is to be published by the U.S. Naval Institute. Brendan was honored at the award ceremony, jointly hosted by Naval History and Heritage Command and the U.S.

Clare Severance ’18, B.S., was recently recognized as one of the honorees on the Society of Manufacturing Engineers’ prestigious 30 Under 30 list. Clare, a senior Manufacturing engineer at Relativity Space, has played a key role in the Terran R next generation launch vehicle program since its launch. Clare also contributed to Relativity Space’s first launch vehicle, Terran 1, the world’s first 3D-printed rocket to reach launch.

Aerospace America published a feature article "U.S. Air Force awards grant for cislunar constellation to track spacecraft and debris” describing a new $1 million grant led by MANE Assistant Professor Sandeep Singh. The grant supports researchers at Rensselaer Polytechnic Institute (RPI) and Texas A&M University to develop the algorithms that would enable such a constellation to operate unobstructed in the notoriously observation-resistant domain of cislunar space.

Congratulations to Professor Amir Hirsa, who will be the next chair of the Science Subcommittee for the International Space Station User Advisory Committee, at the Center for the Advancement of Science in Space. In this role, Professor Hirsa will lead a team to provide input and perspective about the management of ISS Nation

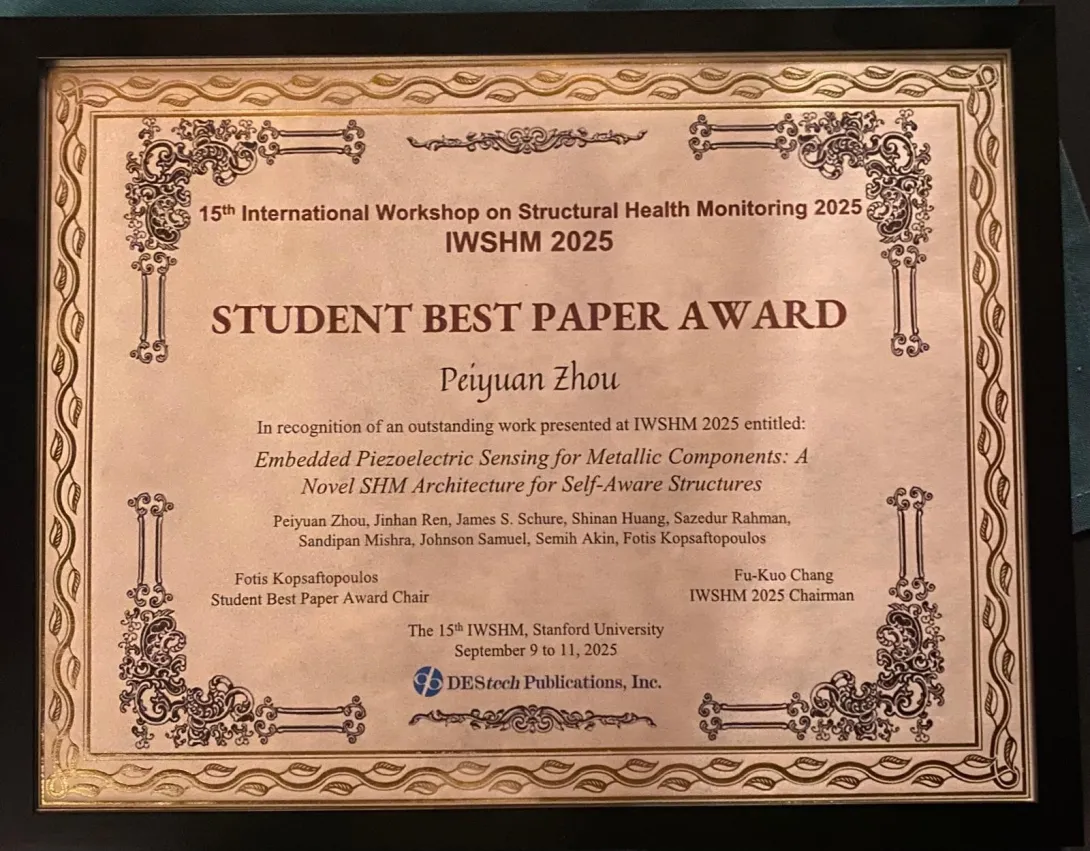

Congratulations to the DARPA team which was awarded the Best Student Paper Award at the International Workshop on Structural Health Monitoring (IWSHM 2025) that took place in Stanford, CA recently. IWSHM is the top international conference on the topic of structural health monitoring and related areas.

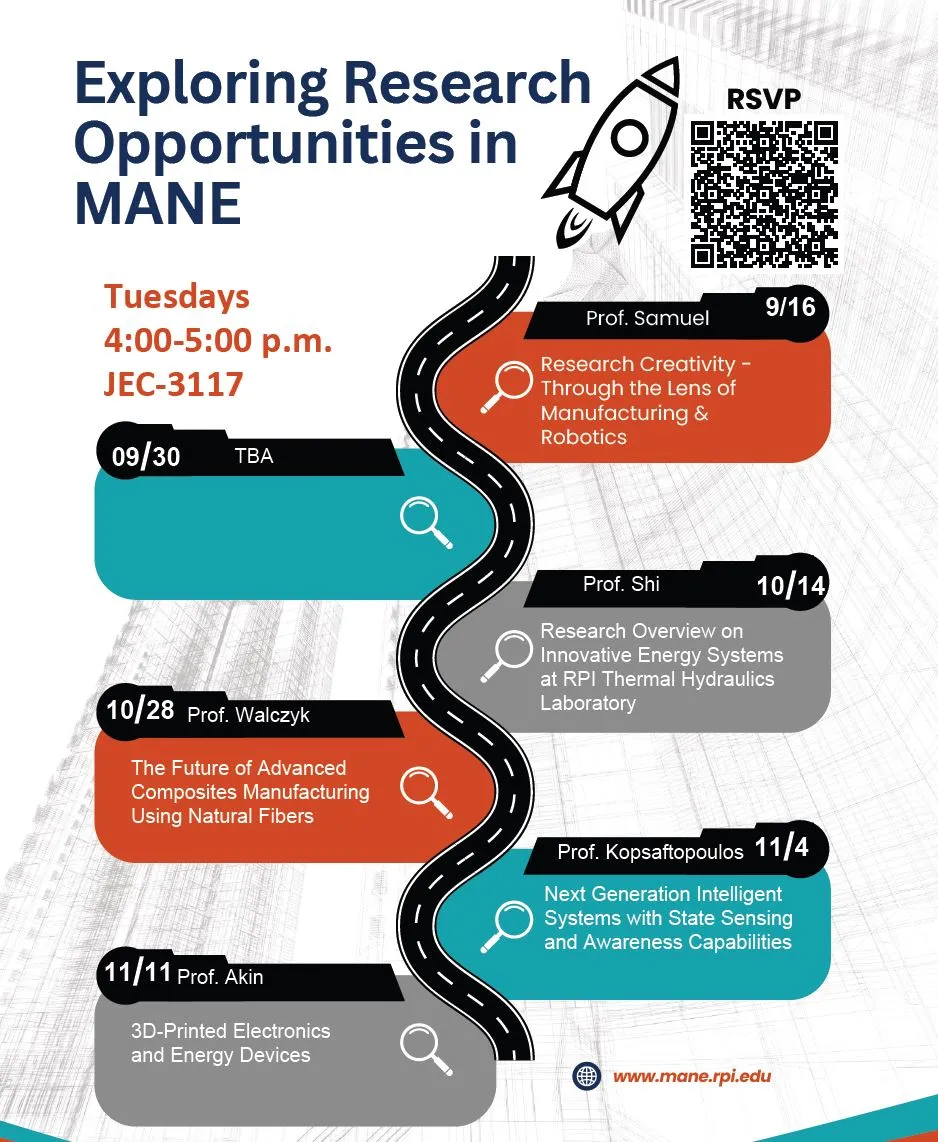

Attention MANE Freshmen and Sophomores!

Have you considered getting involved in research, but just don't know where to start? This series is designed for you! Come hear from faculty about their research and advice to get started! RSVP here for each session.

*ACCELERATED MASTER’S(CO-TERMINAL)

*BS-PHD

*M.Eng., M.S. & Ph.D.TRADITIONAL

Did you know that you could be paid while earning a PhD?

Or, that you could receive a scholarship toward a Master’s degree?

Attend an information session to learn about the exciting research opportunities, program requirements, funding options & application processes to MANE’s graduate programs.

Congratulations to MANE Professor Dr. Shankar Narayan on receiving the HTD Boelter-McAdams Prize at the 2025 ASME Summer Heat Transfer Conference. This award is presented to a member of the Heat Transfer division of ASME that is recognized for their exemplary achievements and contributions to thermal science and engineering.

Congratulations to Dr. Johnson Samuel for being awarded the David M. Darrin ’40 Counseling Award for 2025!

A team of RPI graduates (Joe Adam '17, '18, '21, Tyler Mucci '21, '23, Cesar Gonzalez '20 and Nate Karwic '20) is preparing once again to remotely conduct experiments aboard the International Space Station (ISS). The ring-sheared drop module on the ISS is being utilized to advance our understanding of the flow of complex fluids and develop predictive modeling capabilities.

News